|

The

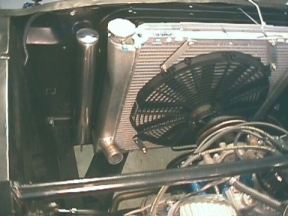

lower mounts were made from 1/8" steel, folded to form a left and

right cradle. The driver's side is shown here, along with how I

drilled two holes and used clipnuts to attach the bracket to the core

support. I experimented with various foam rubber and rubber inserts to

properly space and cushion the side tanks. Notice

the upper retainer is different in this photo than the one above.

The first one was too large and distracting. The bracket shown

to the far left wraps around the tank and secures to the existing upper

radiator bracket hole. No drilling is required. |

|

|

The upper bracket on

the driver's side is not shown in any of these photos, but is not square

like the pax side. That side of the tank is rounded in it's

transition to the pressure cap. The bracket on that side is round,

and follows the contour of the tank. Another option is to use

3" standoffs and run them from the upper flange of the radiator to

the core support. I've seen this installation and it looks very

clean. |

|

Wiring &

Temperature Sensor: |

|

|

Wiring is standard

setup.... us a relay like those listed on my headlight page.

.

| Run

hot signal from a switched battery source.

|

| Main

power comes from a battery term of the Solenoid.

|

| Main

power out to the fan..

|

| Ground

Lead from Fan to Chassis Ground |

| Relay

Signal ground to the Temp sensor, shown here. Shown is a Spal

brand temp sensor. It will turn the fan off/on by reaching

185 temperature and grounding the circuit, turning on the fan.

I almost immediately broke this temp sensor, cracking the top stud

out of the phenolic housing. After that, I went down to AutoZone

and asked for PN SW649. It's a factory version of the same

item and costs about half as much. |

|

|

SPAL Fan

Installation: |

|

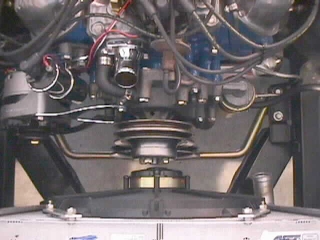

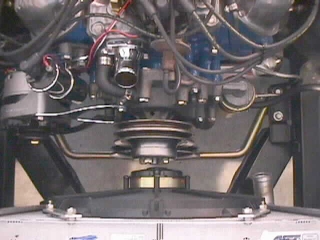

How's

this for clearance. There's all of maybe 3/8" between the fan

and the pulley bolt heads. But a miss is as good as a

mile.

The

fan is a SPAL, 16" puller, rated at 2360 CFM. I chose it

because of it's good reviews, 3.7" depth, and availability on EBAY

for 2/3's the price of retail. Be

prepared tho...this fan has a startup draw of over 25 amps. You need

to have a stout alternator. |

|

|

Battery Tray

Relocation: |

|

|

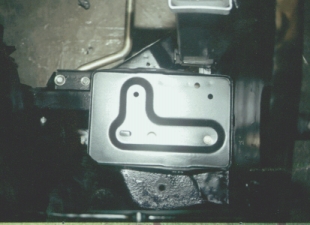

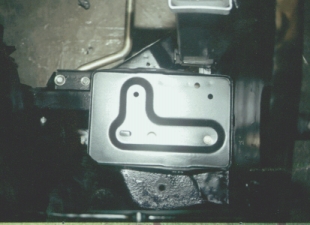

Although not

necessary to install the new tank, changing over to a 69-70 battery tray

provides a lot more room to work.

To install the

tray, the lower leg must be cut and re-bent to allow the tray to sit flush

on the apron shelf. The apron must be 'percussion engineered' as MS

puts it, to allow for the tray to fit outboard as far as possible. I

took the middle approach, and beat the apron to the point that I felt it

could actually tear, and then cut the corner of the tray to clear the

interference. Not the notch in the lower right of the tray in the photo

below.

To reinforce the

mounting, I also installed an 6" long angle brace on the underside of

the shelf. |

|

Looking

straight down on the relocated battery tray. The outboard edge of the tray

lines up with the top of the fender apron. A small pocket still

remains (Thinking about making a block off plate out of sheet metal and

hiding the starter solenoid there.) When

purchasing the 69-70 tray, you will also need the two tie-down posts and

the battery cross brace. Questions?

Email me. |

|

|

20 August 2002 |